Intermodal Freight Solutions: Combining Rail, Road & Sea for Cost Efficiency

The Growing Importance of Intermodal Freight

In today’s global economy, efficiency is everything. Rising transportation costs, capacity constraints, driver shortages, and sustainability goals are pushing shippers to rethink how goods move from origin to destination.

One solution gaining rapid traction is intermodal freight transportation—the strategic combination of rail, road, and sea to move goods in the most cost-effective and environmentally friendly way possible.

Intermodal freight is not new, but the technology and logistics infrastructure supporting it have evolved dramatically. From advanced tracking systems to seamless container transfers between carriers, modern intermodal solutions offer unprecedented control and savings for shippers of all sizes.

What Is Intermodal Freight Transportation?

At its core, intermodal freight refers to using two or more modes of transport—typically truck, train, and ship—to move cargo within the same shipping container. This eliminates the need to unload or reload goods when changing modes, saving both time and cost.

A simple example:

A shipment starts on a truck from a factory in Wisconsin.

It transfers to rail for the long haul to the West Coast.

From there, it moves by ocean vessel to an Asian port for final delivery.

Throughout the journey, the cargo stays in one sealed container, maintaining product security and reducing handling errors.

Why Intermodal Solutions Are Rising in Popularity

Several market forces are driving the resurgence of intermodal freight solutions:

Cost Efficiency

Rail and sea transport are far more fuel-efficient than trucks over long distances. Rail can move one ton of freight nearly 500 miles on a single gallon of fuel, while ships remain the most cost-effective option for international moves. Combining these modes with flexible first- and last-mile trucking creates a balanced, low-cost logistics model.

Capacity Relief

During peak trucking seasons or driver shortages, intermodal networks provide additional capacity. Shippers can shift long-haul freight to rail or sea to free up trucking assets for regional deliveries.

Sustainability Goals

Sustainability has become a key priority for many companies. Intermodal shipping reduces greenhouse gas emissions by as much as 65% compared to over-the-road transport alone. Using lower-emission modes like rail and sea helps shippers meet ESG (Environmental, Social, and Governance) targets without sacrificing performance.

Reliability and Predictability

Rail schedules are typically less affected by traffic and weather than highways, while sea freight offers consistent global routing. This predictability allows for better supply chain planning and inventory control.

Technology and Infrastructure Growth

Intermodal yards, ports, and logistics hubs are now integrated with advanced digital systems. Real-time tracking, electronic documentation, and predictive analytics make coordination between modes faster and more transparent.

How Intermodal Freight Improves Cost Efficiency

Let’s break down how combining rail, road, and sea actually saves money and improves operational performance.

Lower Linehaul Costs

The linehaul—the long-distance portion of the journey—is where intermodal shines. Rail can reduce the cost per mile by up to 40% compared to truckload, particularly on lanes over 700 miles.

Fuel Savings

Rail and sea both consume less fuel per ton-mile. Given the volatility of diesel prices, moving a majority of the distance via rail or ship shields shippers from fuel-cost spikes.

Reduced Labor Costs

Trucking relies heavily on drivers, an area facing ongoing shortages and wage inflation. Intermodal reduces dependency on long-haul drivers by limiting truck use to first and last miles.

Fewer Accessorial Charges

Because freight remains sealed in containers, intermodal moves reduce costs from loading/unloading, storage, detention, and damage claims. The simplified handoffs and less frequent handling lead to fewer unexpected charges.

Equipment and Asset Utilization

Container standardization (20-ft, 40-ft, or 53-ft units) allows for efficient transfer between ships, trains, and trucks. This shared asset model lowers the cost per shipment and allows for better capacity management.

The Intermodal Network in Action

A successful intermodal operation depends on seamless coordination among multiple stakeholders:

Truck carriers handle pickup and delivery.

Rail operators provide long-haul capacity across major corridors.

Ocean carriers connect international routes.

3PLs and logistics providers integrate data, visibility, and coordination across the modes.

Typical Flow Example

Origin Drayage (Truck) – A truck picks up the loaded container from the shipper’s facility.

Rail Transport – The container is transferred to an intermodal terminal and loaded onto a train.

Port Transfer (Sea Leg) – If applicable, the container moves to a port and is loaded onto a vessel.

Destination Drayage – Upon arrival, a local truck delivers the container to the final destination.

This “door-to-door” intermodal model is efficient, secure, and often faster than expected—especially when port congestion or truck driver shortages affect road freight.

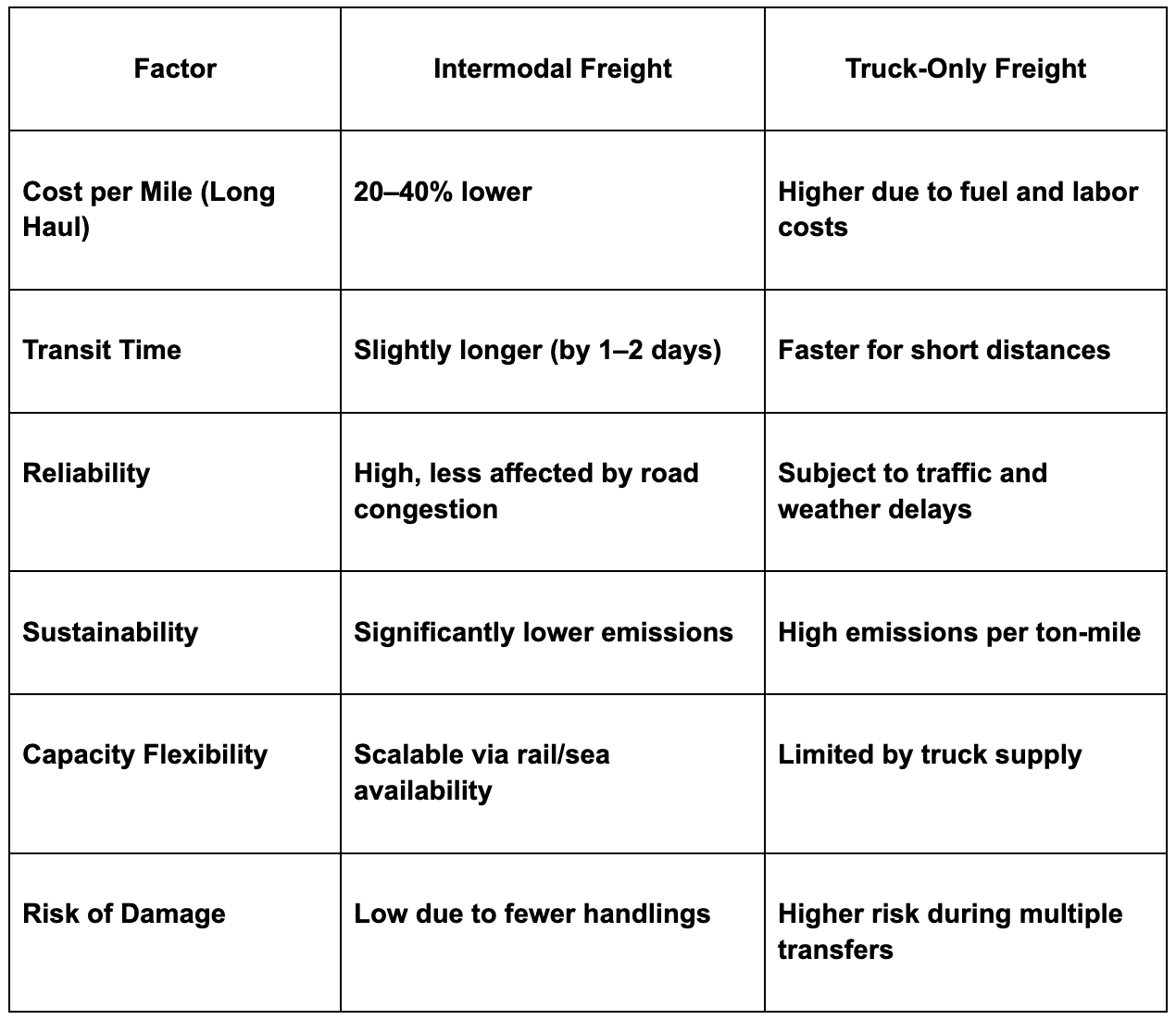

Comparing Intermodal vs. Truck-Only Freight

For many companies, the small trade-off in transit time is more than offset by the significant savings and reliability gains.

The Role of Technology in Intermodal Freight

Modern intermodal logistics relies on digitalization to coordinate the complexity of multiple transport modes.

Real-Time Visibility

Advanced tracking systems allow shippers to monitor containers across every leg—truck, rail, and vessel. GPS, RFID, and satellite data eliminate the “blind spots” that once made multimodal shipping challenging.

Predictive Analytics

AI-driven systems predict dwell times, equipment availability, and port congestion, allowing shippers to make data-based decisions that minimize cost and delays.

Digital Freight Marketplaces

Online platforms now let shippers compare intermodal rates, book capacity instantly, and manage documentation electronically. This increases market transparency and shortens booking cycles.

Integration with TMS and ERP Systems

Intermodal data can now feed directly into a company’s Transportation Management System (TMS), automating freight billing, exception management, and performance tracking.

Sustainability & ESG Advantages

Intermodal transportation is a cornerstone of sustainable logistics. According to the Environmental Protection Agency (EPA), rail freight emits roughly 75% fewer greenhouse gases than trucks per ton-mile. Similarly, ships are even more efficient for global transport.

By reducing carbon emissions and energy consumption, intermodal freight helps organizations:

Meet sustainability commitments

Qualify for green supply chain certifications

Improve brand reputation

Reduce regulatory risk as emission standards tighten

Many major retailers and manufacturers now report intermodal usage in annual sustainability reports as part of their decarbonization strategies.

When Intermodal Freight Makes the Most Sense

Intermodal isn’t ideal for every shipment. It’s best suited for:

Long-haul moves (typically 700 miles or more)

Non-urgent freight where a slightly longer transit time is acceptable

High-volume lanes with predictable demand

Port-to-inland distribution

Shippers seeking carbon reduction or cost savings

It may not be optimal for time-sensitive or short-haul deliveries, where road transport’s flexibility outweighs its cost.

How Shippers Can Get Started

For companies new to intermodal logistics, success starts with the right partners and planning.

Partner with an Experienced 3PL or IMC

An intermodal marketing company (IMC) or 3PL with strong rail and ocean relationships can design efficient multimodal routes and manage cross-carrier coordination.

Evaluate Key Lanes

Identify your most expensive or congested long-haul truck routes. These are prime candidates for intermodal conversion.

Factor in Total Landed Cost

Compare not just rates, but also accessorial charges, handling costs, and time savings. Intermodal often yields a better total landed cost than pure trucking.

Plan for Transit Time

While intermodal is slightly slower than truckload, consistent scheduling and better predictability often offset minor time differences.

Leverage Data and Visibility Tools

Work with providers offering real-time tracking and performance analytics. The more visibility you have, the more value you’ll capture.

The Future of Intermodal Freight

As global supply chains grow more complex, intermodal will continue to evolve. Key trends include:

Expanded rail corridors across North America, including cross-border integration between the U.S., Canada, and Mexico.

Improved port connectivity and inland container terminals closer to major metro areas.

Automation and AI driving predictive scheduling and dynamic routing.

Greater sustainability mandates, making intermodal the preferred mode for eco-conscious shippers.

Digital interoperability, allowing all stakeholders—carriers, ports, 3PLs, and shippers—to collaborate on a single data platform.

In short, the efficiency and resilience of intermodal freight make it an essential tool for future-ready supply chains.

Conclusion

Intermodal freight solutions represent the best of all worlds: the flexibility of trucking, the cost efficiency of rail, and the global reach of ocean shipping. By combining these modes, shippers can cut costs, reduce emissions, and strengthen their logistics networks against disruption.

As markets become more volatile and sustainability demands increase, intermodal shipping isn’t just a smart option—it’s a strategic necessity.

Whether you’re moving freight regionally or globally, now is the time to evaluate where intermodal fits into your transportation mix. The right combination of rail, road, and sea could transform your supply chain from a cost center into a competitive advantage.